The Soil Disrupter

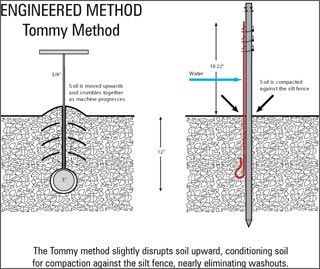

The horizontal chisel point helps to pull the machine into the correct ground depth and helps it maintain that depth. It also disrupts the soil upward, usually with minimal displacement. You do not have to push it into the soil; it pulls itself in!

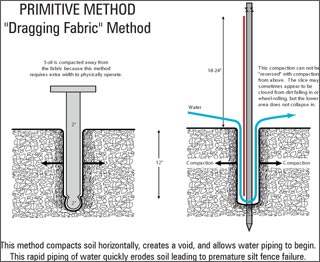

This is critical for two reasons. One, just slicing the soil with a blade, like a vibratory plow, compacts the soil horizontally, preventing the soil from collapsing onto the fabric and retarding its ability to be compacted tightly against the fabric — extremely critical! A vibratory plow installation is not acceptable. In addition, running the chisel point deep in the ground, possibly 18” deep, may not disrupt the soil upward — it could act similarly to the vibratory plow and compact the soil horizontally.

Two, disrupting the soil upward creates an optimal condition for mechanical compaction, especially wheel-rolling with the power source. Minimal time, labor and equipment are required for compaction — both critical factors in contractor adherence to the specifications.

Minimal soil disruption and displacement maintain some of the soil's original profile enabling compaction back to its original state, insuring greater soil stability, and thus greater resistance to washout.

Minor disruption minimizes soil moisture loss during fence construction, which also contributes to high relative compaction.

The slicing method nearly eliminates washouts. The word nearly is used because other factors such as the machine operator, the weight and repetitions of compaction, trash in the soil, soil structure, and moisture can all effect the outcome.